Bringing Passion and Enthusiasm

to the Future of Materials AdvanHeat

HIROCHIKU draws on thermal and other state-of-the-art technologies developed over the years since its founding to propose production processes that have been optimized to meet customers’ needs and to design and manufacture heat treatment systems.

By augmenting our long track record of successful projects and ceaseless in-house technological R&D with new overseas technologies, we're able to propose a broad range of technologies encompassing everything from research to manufacture in the area of new materials.

Typical Examples of New Material Development

ITO for thin panels; semiconductor circuit boards; polycrystalline silicon (for solar panels); light-emitting diodes; fluorescent materials; piezoelectric elements and capacitors; quartz glass; lithium-ion batteries and fuel cells; activated charcoal, tyranno fiber, and carbon nanotubes (CNT); catalysts; precious metal refining and recycling (platforms); artificial bone; powder metallurgy (PM) and metal injection molding (MIM); super-hard and magnetic materials

Equipment Introduction

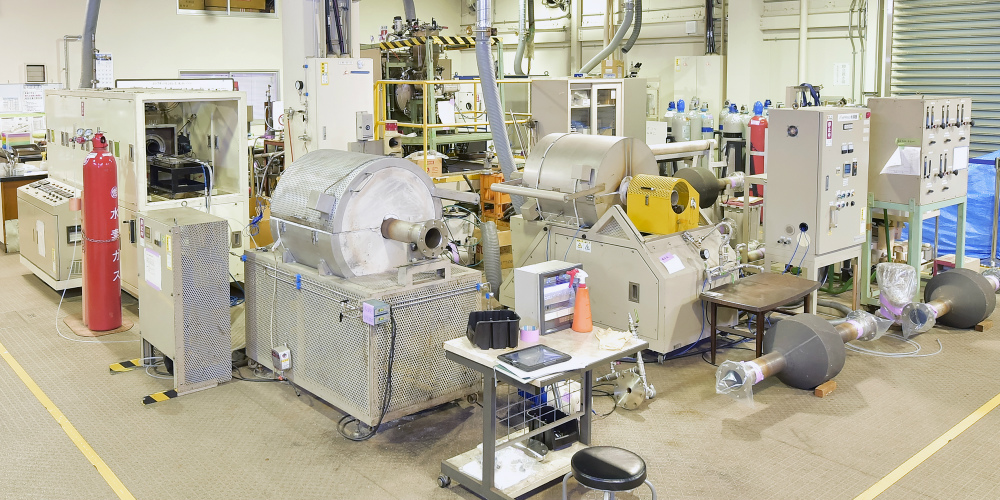

Sample Baking Test

Business Development

Projects in Progress

Supporting Operations at a Plant That Manufactures LCD Panels

for Use in the World’s TVs and Smartphones

Developing a Sintering Furnace for ITO (Transparent Conductive Film) for Thin-Film Panels

LCD panels use transparent, highly conductive electrodes made from a material known as ITO. ITO sintering furnaces, which are used to sinter spattering targets, must deliver heat in a precise manner.

HIROCHIKU began developing an ITO sintering furnace around 1988, and our track record of deliveries has grown steadily since.

The team succeeded in developing technology capable of precisely creating and controlling temperature distribution in a high-temperature atmosphere.

More recently, the team has come together to meet customers’ needs for demanding specifications, for example by developing larger furnaces to accommodate significantly higher treatment volumes and by developing equipment that differs completely from previous designs in terms of shape. Team members continually embrace technological challenges, for example by striving to increase equipment durability.

Hirochiku ITO sintering furnaces help underpin production of the world’s TVs and smartphones.

World Strategy

New Material Development Equipment

Overseas Delivery Records

- We've delivered systems to customers in China, South Korea, Thailand, and the U.S.A.

- The number of inquiries from overseas research and manufacturing facilities has been growing, as has our track record of deliveries.

| South Korea | Inchon, Gumi, Gunsan, Jeonju |

|---|---|

| China | Ningxia, Zhuzhou, Jiaxing, Wuhu |

| Thailand | Chonburi |

| U.S.A. | Rhode Island |

Main Industry

- Electronic Components and Semiconductors

- Solar Panels

- Ferromagnetic Materials and Hydrogen Adsorption

- Wiring

- Fuel Cells

- Lithium-Ion Batteries

- Pharmaceuticals

- Optical Devices

- Catalysts

- Abrasives

- Super-High-Purity Refining

- Recycling

- Material and Raw Material Manufacturing

- Space Development

- Government and University Labs

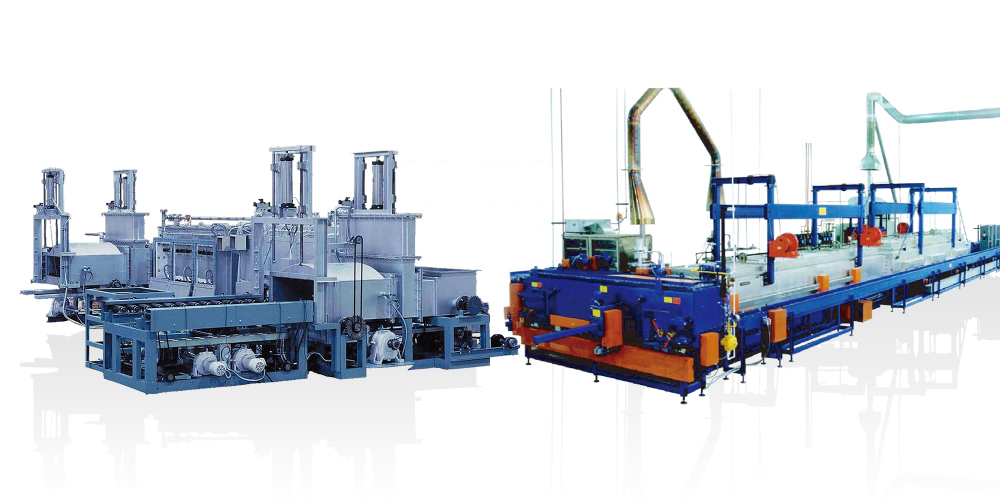

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat Treatment Equipment

Metal Heat Treatment Equipment