Features

Installation Technologies and Furnace Construction Skills Accumulated since Our Founding

We offer leading installation technologies and furnace construction skills in the area of firebrick installation, a core technology in industrial furnaces.

Satisfying Customer Needs by Accommodating a Diverse Array of Materials

Our capabilities include brick installation for facilities such as blast furnaces, air-heating furnaces, coke ovens, and glass furnaces as well as wet spray-on installation and paper-lining installation inside furnaces.

Training Highly Skilled Furnace Construction Technicians

Our technicians pass down and continue to advance furnace construction techniques. Our top priority is to train such technicians, who form the basis of our business.

Refractory Construction

Business Execution

Heat Treat Furnace Construction

Design of Refractory Materials for Heat Treat Furnace

Since our founding, we’ve developed extensive expertise and accumulated some of Japan’s leading technologies.

Work Meeting

Work meetings serve to articulate work tasks and roles and to ensure quality control.

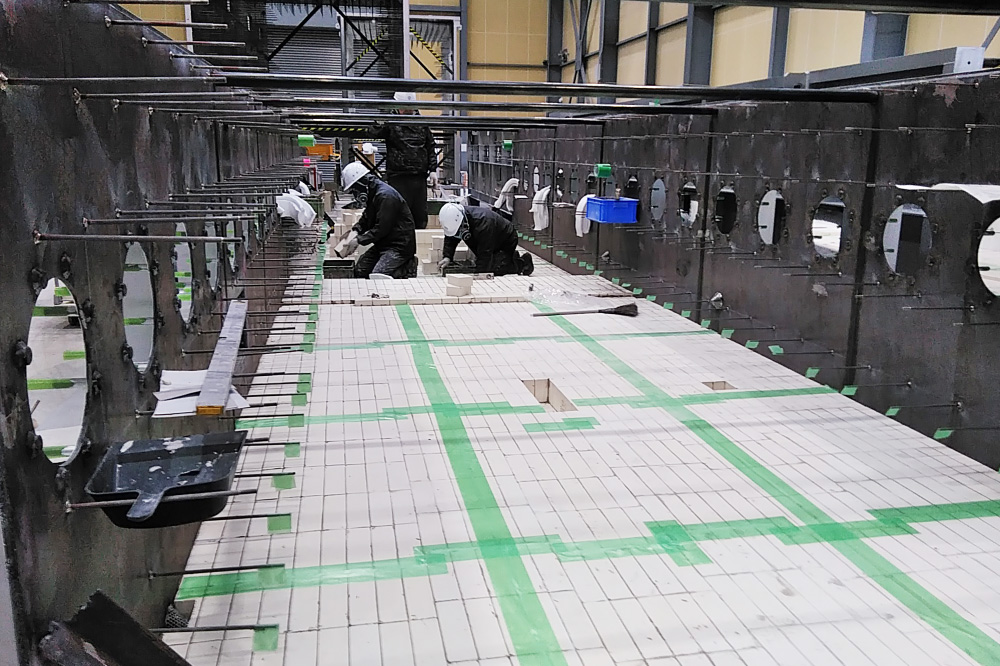

Brick-Laying Work

Craftsman skill and standardization designed to streamline work come together in brick-laying.

Main Customers

- NIPPON STEEL CORPORATION

- Sanyo Special Steel Co., Ltd.

- Godo Steel, Ltd.

- Yamato Steel Co., Ltd.

- OSAKA STEEL CO., LTD.

- SHINKANSAI STEEL CORPORATION

- Toho Titanium Co., Ltd.

- Nippon Denko Co., Ltd.

- Kansai Coke and Chemicals Company, Limited.

- NIPPON STEEL ENGINEERING CO., LTD.

- Chugai Ro Co., Ltd.

- Sumitomo Heavy Industries, Ltd.

- YOTAI REFRACTORIES CO., LTD.

- KROSAKI HARIMA CORPORATION

- SHINAGAWA REFRACTORIES CO., LTD.

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment