Features

HIROCHIKU offers a wide range of services including technical services that propose the best solutions for your needs, maintenance services that deliver assurance, and sample testing services to help you appreciate our product performance.

HIROCHIKU’s contract service undertakes the customers’ heat-treatment process.

Heat treatment technology consultations, seminars and simulations

HIROCHIKU quickly responds to maintenance, inspection, and various measurements, including temperature distribution measurements.

Demonstrations of performance and quality, and more than 10 different trial machines

HIROCHIKU accepts heat treatment processing in its furnace that was developed in-house.

Technical Services

Consultation for Heat Treatment Technology

We propose the best solutions for your requirements, based on our experience of over 50 years. Our sales staff has the technical knowledge to provide consultations for your specific needs.

Seminars

We provide seminars on themes such as heat treatment basics, heat treatment properties of materials, tips on using our products and our product performance.

The seminar highlighted actual heat treatment applications showing data on quenching of high-speed and die steel using the new SAM type multi-purpose heat treatment equipment. The event attracted great interest from the 200 attendees. These seminars have a good reputation.

Click here for information on seminars in detail.

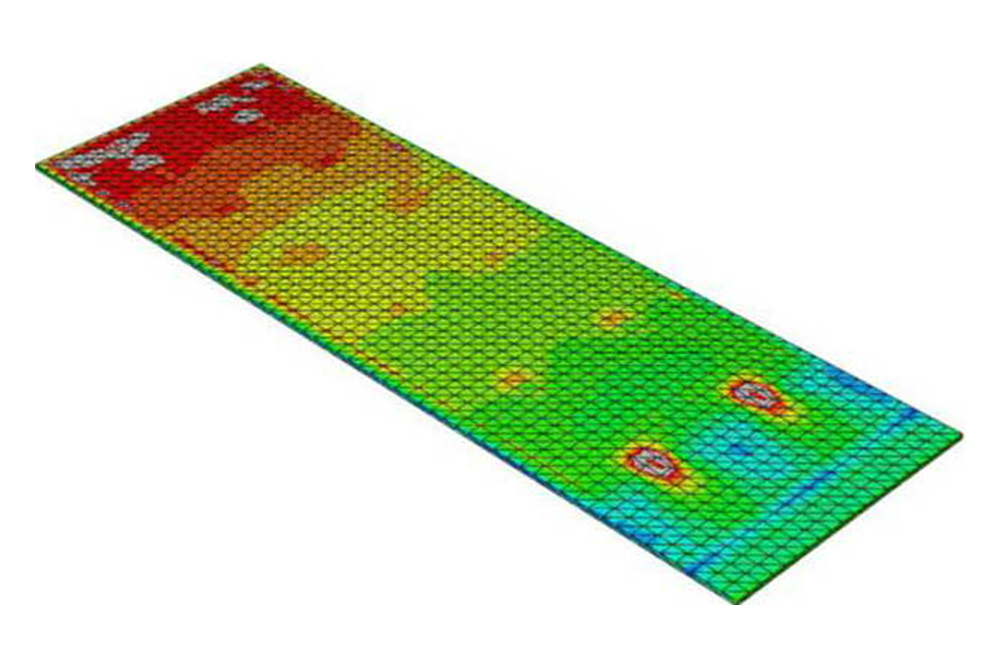

News from ThermalSimulation (structual and flow analyses)

HIROCHIKU adapts the results of the behavior of natural temperature materials in a wide variety exported to a simulated heat environment to the designing of furnace structure thickness and reinforcement methods and the troubleshooting of furnaces.

For more details

Contact UsMaintenance Service

This photo shows our maintenance team working on furnace inspection and repair. Our team provides periodic maintenance for more than 6,000 furnaces around the world, as well as emergency maintenance services to address unexpected problems.

Quick Responce

Our maintenance team quickly responds to customer problems. To enhance customer convenience, our sales staff is also familiar with maintenance techniques.

In case of any problems

Contact UsInspection, Calibration and Temperature Distribution Measurement

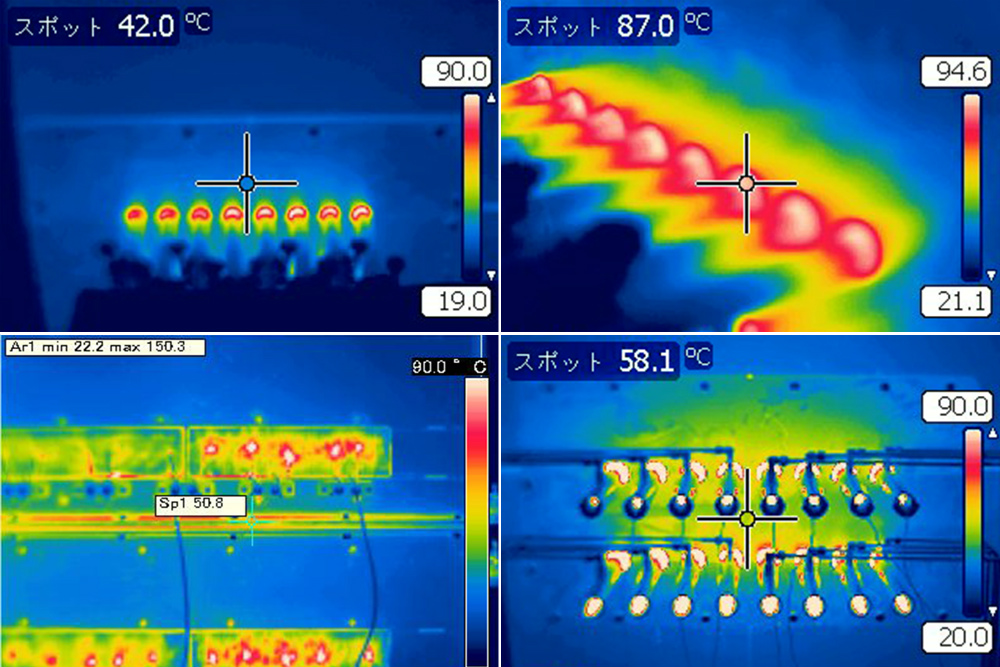

Heat treatment is a special process, so we recommend periodic inspection and calibration to prevent problems. For inspecting temperature distribution, which is critical to ensure high quality, measurement can be performed under conditions including empty furnaces, implementation, work temperatures and batch/continuous method.

A special process is where the product quality specific to the process can only be achieved by precisely implementing the process (i.e., inspection cannot determine the quality) and defects can only be found later on (when the product is used).

Surface temperature measurement using thermography is also possible.

For inquiries about measurement/inspection services

Contact Us

Sample Testing

We provide sample testing services for customers who wish to thoroughly check our product performance and actual products for yourself.

More than 10 furnace units are always available.

- Various types of heat treatment can be tested on various types of furnaces.

- You can check the performance of the model (or a similar one) that you are considering.

Few manufacturers make more than 10 units of test equipment available.

Sample testing services are also available in Vietnam.

- Sample tests of hardening (oil/water quenching) and tempering using an atmosphere furnace can be conducted at our affiliate plant near Hanoi. (Materials applicable to Japanese standards: SK, SKS, SCM, SUJ, S--C, SKD, SKH, etc.)

For inquiries about sample testing

Contact Us

Lineup of Test Equipment (partial)

| Type | Features |

|---|---|

| High-temperature quenching furnace for oil-cooled and air-cooled steel |

|

| Hydrogen atmosphere continuous furnace |

|

| Fully automated cyclic tempering furnace |

|

| Shaker hearth furnace |

|

| Carburizing and quenching furnace |

|

| Non-oxidation quenching furnace with oil bath |

|

| Medium-temperature drying furnace |

|

| Box type heating furnace |

|

Heat Treatment Contract Processing Service

With HIROCHIKU’s Thermal-brand heat treatment system at its Nasu Plant (in Tochigi Prefecture), HIROCHIKU performs heat treatment processing at customers’ requests. HIROCHIKU derives optimal heat treatment conditions according to customers’ requests and performs high-quality heat treatment. Please feel free to contact us.

Available and Acceptable Heat Treatment Processing Items

- Annealing

- Solution treatment

- Quenching

- Brazing

Click here for details on HIROCHIKU’s heat treatment processing service.

Details

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment