Realizing the Full Automation of

Melting and Molten Metal Distribution Equipment

in Die-Casting Factories

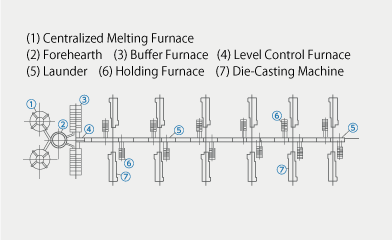

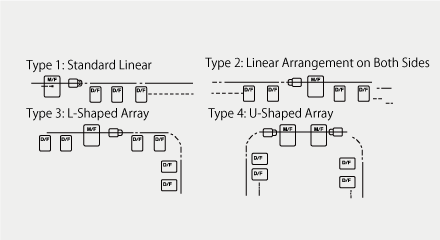

HIROCHIKU proposes optimal molten metal transfer systems (e.g., launder systems or carrier systems) for customers,

with consideration of the customers’ specifications and arrangements of melting furnaces or dosing furnaces, and their functions and convenience based on the customers’ production plans.

Proposal for Factory Layout Plan

-

Production Planning

Product Varieties, Production, Operating System, Fuel, etc.

-

Installation Plan

Die-Casting Machine

-

Specification Change

Melting Furnace and Dosing Furnace

-

Launder System

Carrier System

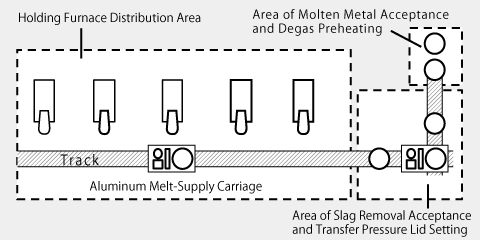

Automatic Aluminum Melt-Supply Carriage System

Operation Line Change Plan Procedure Example

HIROCHIKU also plans to change the current operation line.

-

Current

Forklift Transport Method

Dosing Furnace Method

-

-

Suggestions

Fully Automatic Centralized Melting Method

Launder System

Carrier System

Automatic Aluminum Melt-Supply

Carriage System

Selection of Dosing Furnace Specifications

- Standard Holimesy Dosing Furnace (Model C)

- Immersion Heater-Type Horizontal Holimesy Dosing Furnace (Model E and Model VE)

- Gas Radiation Dosing Furnace (Model HG and Model G)

Factory Layout Planning

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment