Features

We Design Casting Plant Layout.

We propose plant layout designs and reviews to deliver energy savings while maximizing production efficiency.

We Deliver Efficient, Safe Designs by Providing Solutions Consisting of Hirochiku Equipment.

In addition to our flagship lines of centralized melting furnaces, automatic aluminum melt-supply carriage equipment, and dosing furnaces, we provide peripheral equipment such as heat treat furnaces, dust collectors, and transport conveyors.

We Deliver the Same High-Quality Support in Our Overseas Business.

We offer high-quality support to overseas plants through a network of overseas subsidiaries and local partners.

Melting Furnace

We supply tower-type rapid melting furnace. Highly efficient melting performance allows these products to use less energy and power while reducing metal loss.

Centralized Melting Furnace (HM III)

The Hurry Melter III meets a broad range of diversifying customer needs with a compact design that simplifies cleaning and inspections while delivering energy savings, low-power melting performance, and reduced melting loss as a master furnace.

Dosing Furnace (HM II)

The Hurry Melter II is a melting and dosing furnace designed to realize improved melt quality while delivering significant improvements in aluminum leak resistance and reduced oxidation loss.

Transport Equipment

Our melt distribution systems deliver unattended melt transport capability. Components include a trough-based launder system and a monorail-based carrier system, automatic aluminum melt-supply carriage system.

Carrier

This unattended system automatically loads melt into a ceramic ladle that moves on a monorail to transport the liquid from a melting furnace to a dosing furnace.

Launder System

Consisting of a launder (melt supply trough) developed by Grenges Ueda and a Holimesy dosing furnace, our launder system brings unattended melt distribution to die-casting plants.

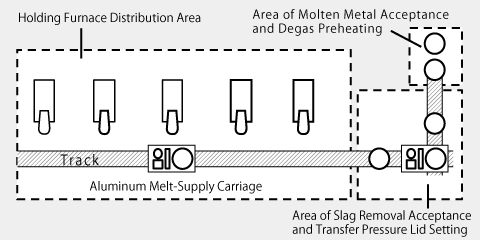

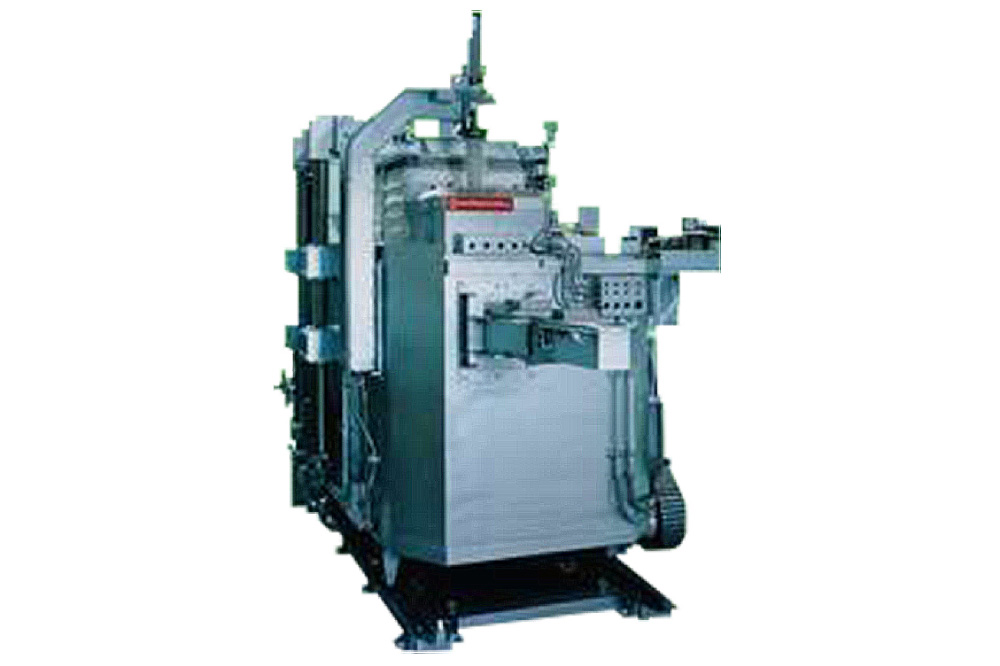

Automatic Aluminum Melt-Supply Carriage System

This automatic aluminum melt-supply carriage system features safe, unattended operation. Using carts designed to transport sealed containers without melt leakage, this system uses weight control to deliver a pressurized melt supply.

Dosing Furnace

Our energy-saving, electric-powered products have become the standard in aluminum dosing furnace thanks to their exceptional insulation performance and creative design.

Holimesy Dosing Furnace (Model C)

This Holimesy system has become the standard in aluminum dosing furnaces. Its exceptional insulation performance and multi-chamber design minimize energy consumption while eliminating hard spot formation.

Holimesy Dosing Furnace

(Model E/Model VE)

This immersed-heater type Holimesy dosing furnace delivers high efficiency while delivering the many advantages of Holimesy dosing furnaces.

Holimesy Dosing Furnace (Model HG)

This gas-radiation type Holimesy dosing furnace incorporating many of the features of conventional electric-radiation type Holimesy dosing furnaces.

Holimesy Dosing Furnace (Model G)

Designed to make the most of the features of Holimesy furnaces, this gas-fired dosing furnace uses a flat burner on the ceiling to limit oxide formation and metal loss.

Low-Pressure Casting Furnace

Our no-crucible dosing furnace supply melts at uniform pressure. They're also available in a two-chamber design that consists of a holding chamber and a pressurization chamber.

Low-Pressure Casting Furnace (Single-Chamber Type)

These no-crucible electric dosing furnaces are designed for use in low-pressure casting systems. They can be equipped with a radiant tube system or an immersed heater.

Low-Pressure Casting Furnace (Two-Chamber Type)

In this design, the pressurization chamber remains closed while melt is supplied to allow continuous operation. These compact, low-pressure casting furnaces feature stable pressurization control and minimal variation in the melt level in the pressurization chamber.

Direct Feeding Furnace

These feeding furnaces are designed to be connected to a sleeve from a die-casting machine. A constant melt level is maintained in the tapping chamber to ensure highly precise melt supply volume.

Direct Feeding Furnace (Float Type)

These fully automated feeding furnaces, which are designed to be connected to a die-casting machine’s sleeve and dosing furnace, are engineered to supply melt at high precision, and they feature a mechanism for maintaining a uniform melt level in the tapping chamber so that melt is not exposed to the air.

Heat Treat Furnace

Our heat treat furnaces automatically perform solution heat treatment and age-hardening treatment of aluminum alloys. They are available in electric and gas variants.

Heat Treat Furnace (Electric)

Our electric heat treat furnaces deliver exceptionally uniform quality thanks to temperature management and other features designed to boost the strength of aluminum products. Either batch or continuous furnace is available.

Heat Treat Furnace (Gas)

Our gas heat treat furnaces automatically perform solution heat treatment and aging treatment of aluminum alloys. Either batch or continuous furnace is available.

Auxiliary Equipment

We study specifications of auxiliary equipment such as dust collectors, conveyors, and flux feeders.

Flux Feeders

We offer a selection of other manufacturers’ powder supply systems for injecting flux into molten aluminum.

Dust Collectors

We offer a selection of other manufacturers’ cyclone dust collectors, bug filter dust collectors, and wet-type dust collectors for use with melting furnaces.

Conveyors

We offer a selection of other manufacturers’ transport systems.

Business Execution

Design

The extensive range of technologies we’ve accumulated over our history has made possible the high-quality Holimesy brand.

Trial Run Adjustments

The Hirochiku Product Center carries quality control in a rigorous manner.

Team

Our sales, design, and manufacturing teams work together to provide an unparalleled level of customer support.

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment