Recommended Thermal Standard Series of Heat Treatment

Continuous Bright Heat Treatment Furnace

Using Hydrogen GasBCE Series

Treating stainless steel in reducing atmosphere (hydrogen, hydrogen and nitrogen, ammonia decomposition gas) reduces any oxides on the surface, achieving a bright (glittery silver white) treatment.

HIROCHIKU's BCE series continuous furnaces for bright treatment have been installed on many sites both in Japan and overseas.

Target Works (Typical Examples)

Heat Treatment Methods

Annealing, solution heat treatment, quenching and brazing

Examples

- Transportation

- Pipes for automobile components, automobile parts, disc brakes, bellows, pressed parts

- Construction

- Flexible pipes (gas and water pipes), stainless steel pipes, building reinforcement parts

- Cutting tools

- Medical devices, tableware, kitchen knives, scissors, tools

- Equipment

- Heat exchangers, hydraulic equipment, gas appliances, farm equipment parts

- Precision parts

- Watch bands and parts, IT device parts, jewelry

Features

Works to be treated are continuously transported on belt conveyors so that they can be fed to the next process without a break.

Although hydrogen-based gases are used, a safety device is incorporated to ensure safe operation.

The more than 300 continuous furnaces that have been installed on sites in Japan and overseas demonstrate reliability.

Services

- A gas analysis system and alarm system are ready as options to enable stable bright treatment at all times.

- For parts that require quick cooling, a hydrogen gas circulation type cooling system can be installed in the cooling zone.

Shape

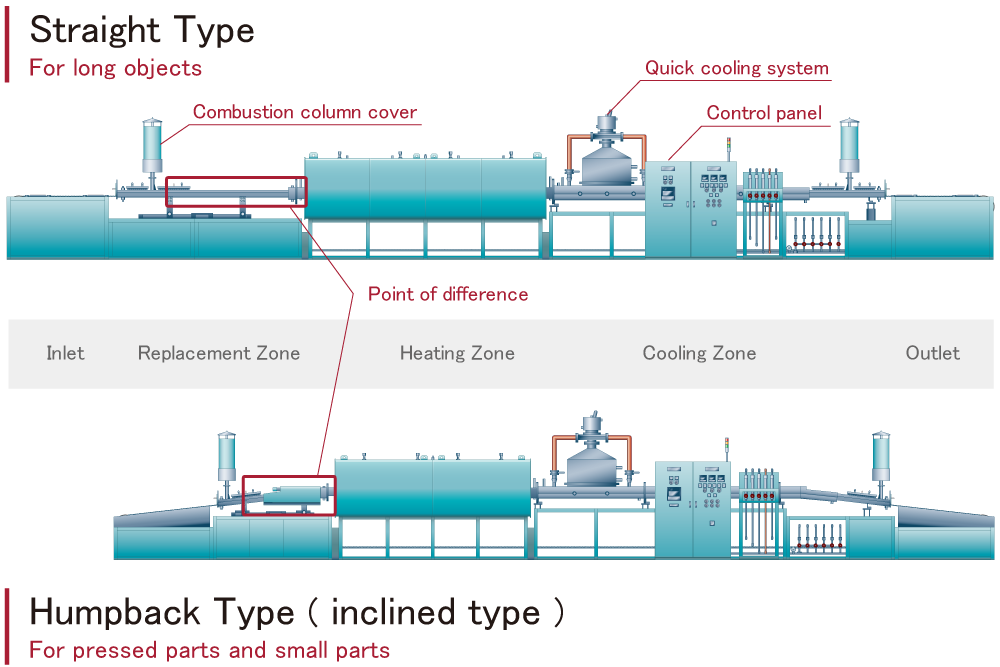

Since the straight type for long objects (such as pipes and round bars) has a straight structure from the inlet to the outlet, providing a long replacement section from the inlet to the heating area ensures stable replacement between air and hydrogen in the treatment pipe, enabling extremely long objects of all lengths to be processed.

The humpback type for pressed parts and small parts has an inclined inlet and outlet, reducing atmospheric gas consumption while maintaining a stable furnace atmosphere. Works to be treated are placed on the belt conveyor, which transports them at a constant speed. The belt passes the preheating (replacement), heating and cooling zones before reaching the outlet with the cooled works on it.

More about C Series

Details

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment