Recommended Thermal Standard Series of

Heat Treatment

Multi-Function Heating Treatment FurnaceSAM

Quenching and Annealing under the right conditions for each type of steel improves material hardness, reduces distortions and extends die life. With SAM, HIROCHIKU provides solutions to your heat treatment problems.

Target Works (Typical Examples)

Heat Treatment Methods

Quenching and annealing

Examples

- Dies

- Cold work tool steel:

Caulking, deep drawing, forging, dies, stamping, etc. - Hot work tool steel:

Die-casting, casting molds, forging, dies, etc. - High-speed tool steel:

Drills, end mils, taps, reamers, etc. - Molds for plastics:

Injection molds, etc.

- Cold work tool steel:

- Tools and jigs

Probes, collet chucks, punches - Parts

Gears, springs, clutches, bearings, screws, chains, etc. - Products

Latch needles, fish hooks, pocket knives, kitchen knives, saws, etc.

Features

Quenching oil-quenched, nitrogen-gas-quenched and high-speed steel can be performed by a single unit.

Space-saving installation.

Easy automated operation using programs.

Six-panel heater ensures excellent temperature distribution.

Muffleless structure and unit heater enable easy maintenance.

Services

Hirochiku offers advice on treatment heat patterns.

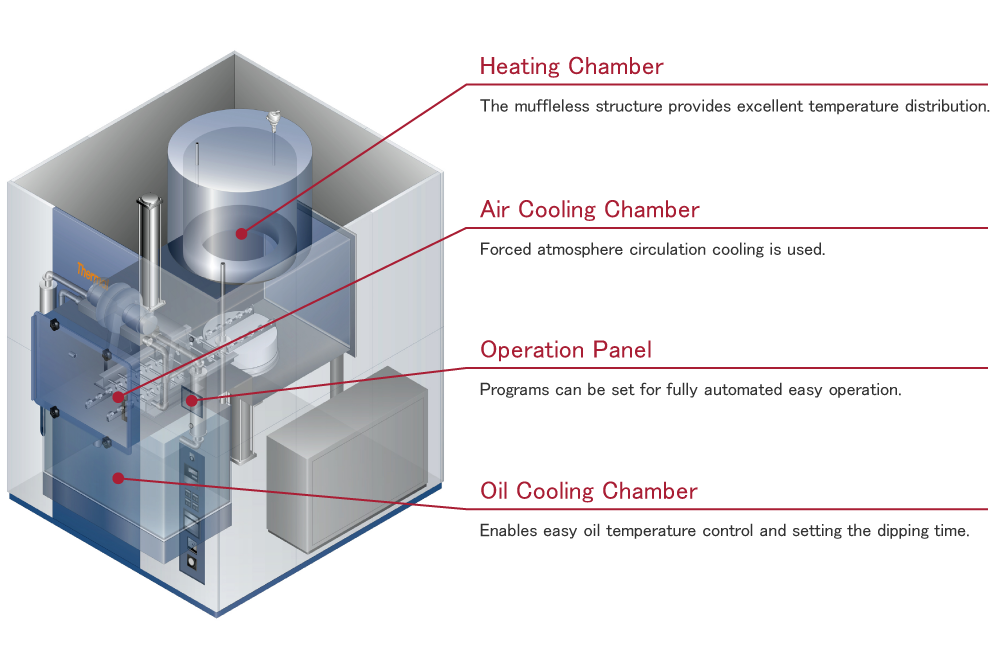

Structure

Transparent View

Main Specifications/SAM50

| Heating chamber temperature | 600 to 1250 ℃ |

|---|---|

| Oil bath temperature | 120 ℃ or less |

| Effective treatment dimensions | φ400 x H300 mm (including tray height) |

| Treated weight | 60 kg/gross |

| Power supply | 3-phase, 200 V, 31 kVA |

| Treatment atmosphere | Nitrogen, etc. |

| Target steel materials | SC, SK, SKS, SUJ, SKD, SUS, high-speed steel |

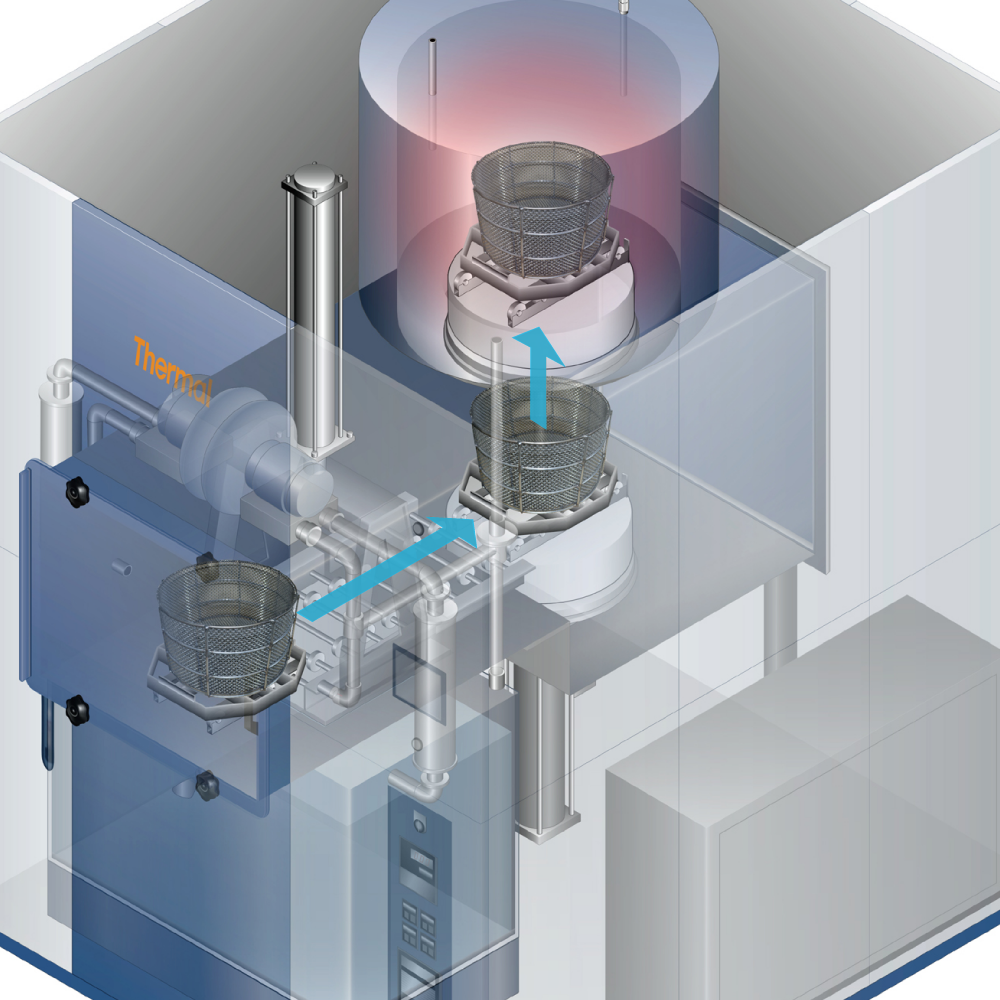

Automatic Feeding Operation

Heating

Work that is set in position is automatically fed to the heating chamber.

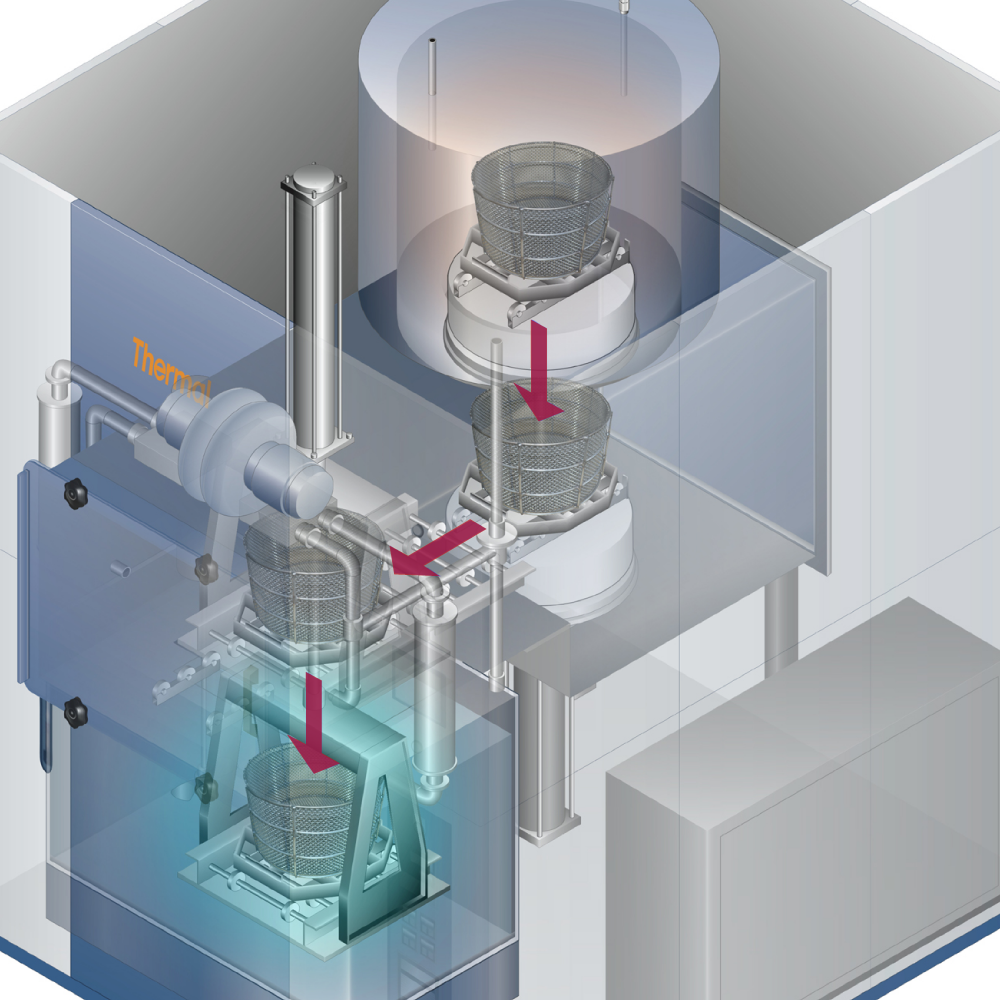

Oil Cooling

Heated work is automatically fed to the oil cooling chamber (oil bath).

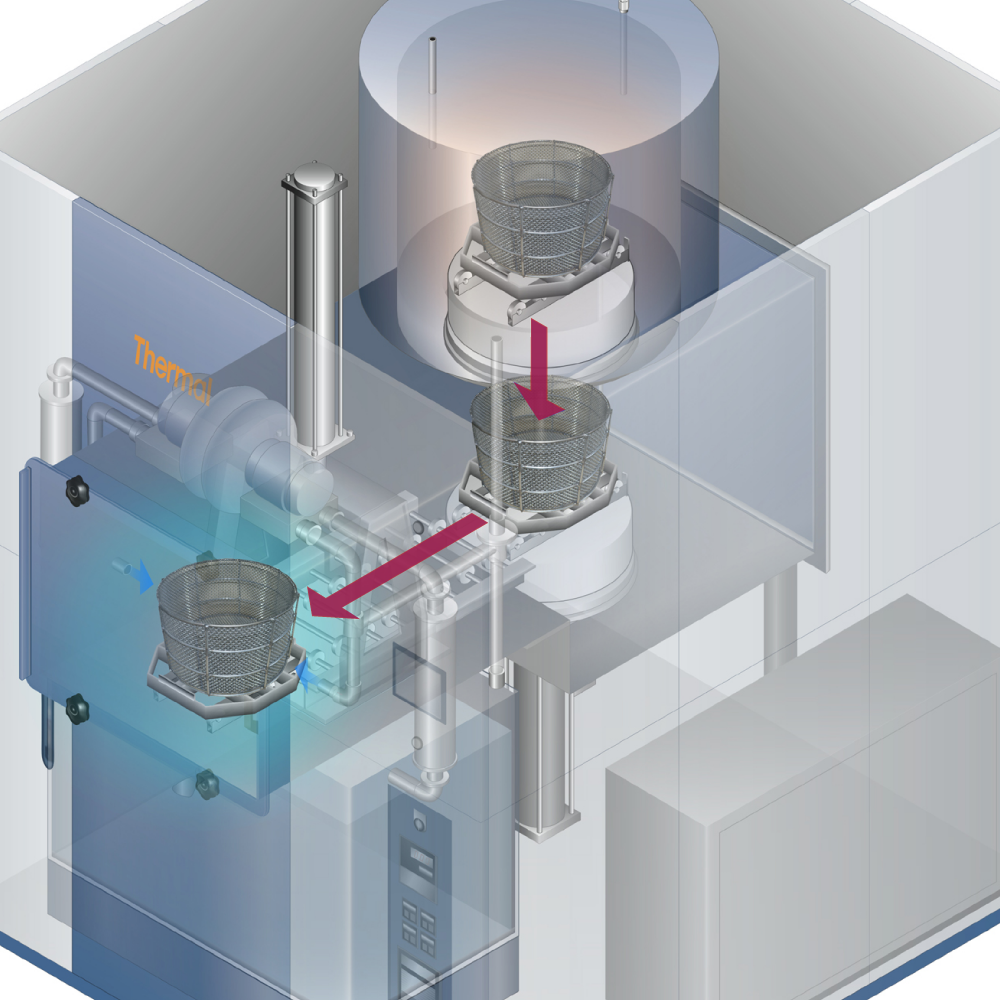

Air Cooling

Heated work is automatically fed to the air cooling chamber.

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment