Features

Models in this series are widely used for tempering, annealing, age hardening, shrink fitting, baking and various types of drying in a medium temperature range.

They can also be used for aluminum solutionizing and age hardening.

RBM/RHAirflow Type, High-temperature Furnace

Best suited for tempering

| Applications | Tempering of steel (low to high temperature), shrink fitting, stress removal after welding and T4/T5/T6 treatment of aluminum |

|---|---|

| Features |

|

| Temperature | 100 to 550℃ (RBM) 100 to 630℃ (RH) |

| Treated weight | 50 to 100 kg/gross |

About the large type (RBT/N series)

DetailsTAF/TAF-HFully Automated Cyclic Tempering Furnace

Fully automated tempering furnace with cooling function

| Applications | Tempering of steel (low to high temperatures), shrink fitting, stress removal after welding and T4/T5/T6 treatment of aluminum |

|---|---|

| Features |

|

| Temperature | 100 to 550℃ (TAF) 100 to 630℃ (TAF-H) |

| Treated weight | 50 to 100 kg/gross |

RONSimplified Atmosphere Annealing Furnace

Atmosphere heat treatment is the most effective for reducing coloration and oxidation

| Applications | Atmosphere tempering, annealing of copper, age hardening of beryllium copper and tempering of spring materials |

|---|---|

| Features |

|

| Temperature | 100 to 530℃ |

| Treated weight | 30kg |

| Atmosphere | N2 |

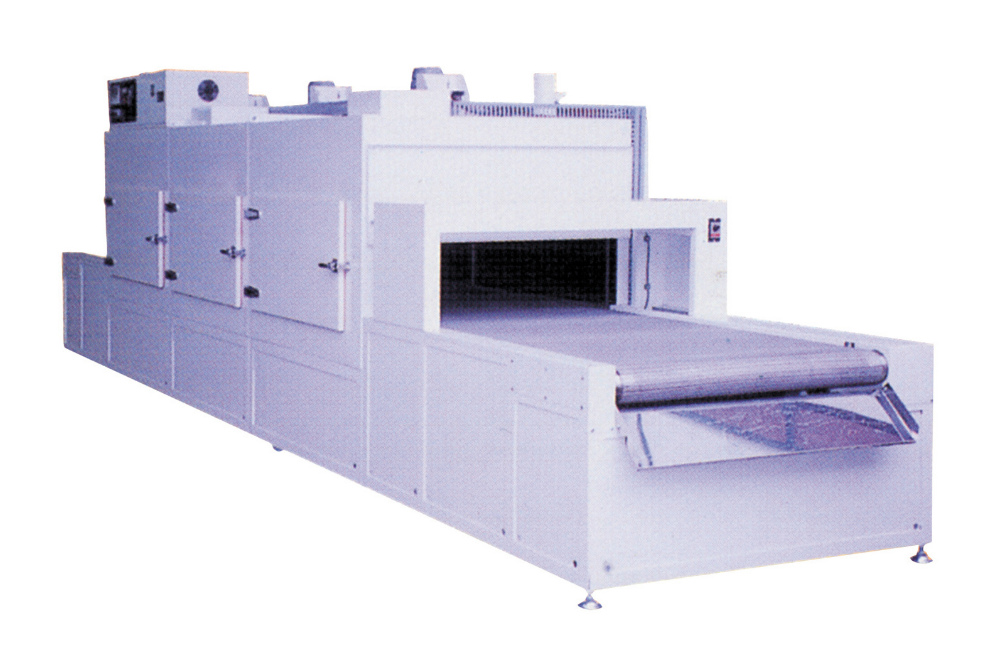

RBCHot Gas Circulation Conveyor Furnace

Suitable for in-line tempering process after induction hardening

| Applications | Tempering after induction hardening, low-temperature tempering and annealing of steel, and glass firing |

|---|---|

| Features |

|

| Temperature | 100 to 450℃ |

| Heating time | 2 to 70 min |

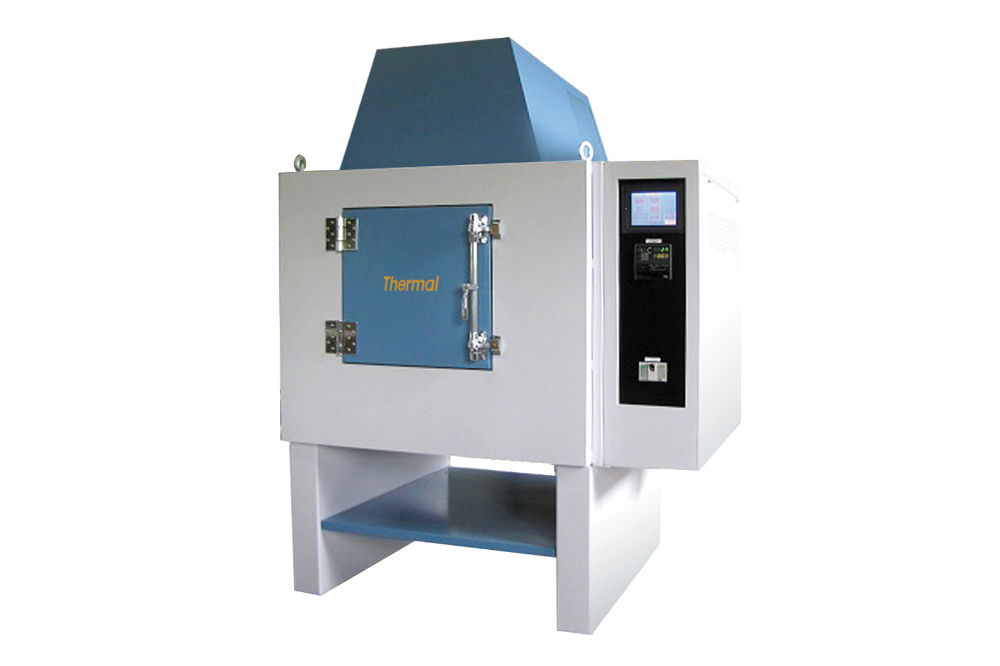

RBHPrecision Middle-temperature Heat Treatment Furnace

Medium-temperature type with excellent temperature distribution

| Applications | Tempering and annealing (low to medium temperatures) of steel materials, baking treatment after plating and T5 treatment of aluminum |

|---|---|

| Features |

|

| Temperature | 100 to 560℃ |

| Furnace volume | 0.2m³ to 2.25m³ |

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment