Features

Various types of continuous heat treatment furnaces for volume production of pressed and machined parts are available according to the material and shape of the target work.

Hundreds of Thermal’s continuous furnaces have been installed at sites in Japan and overseas, and are used in a wide range of areas.

Upon request, we can also test and prototype your product samples to propose the optimum conditions.

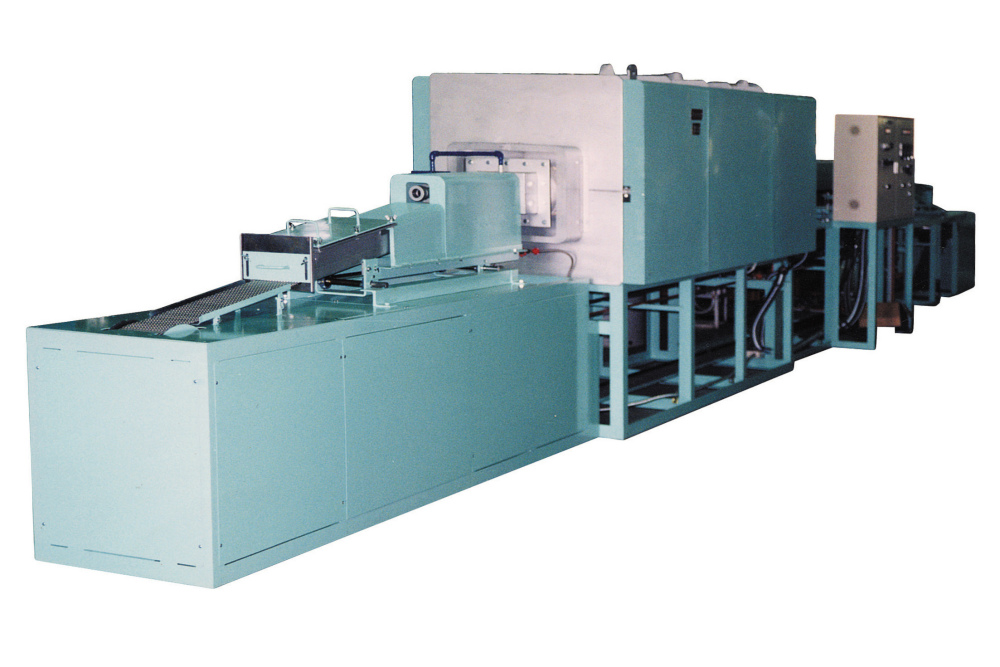

BCE(A)Stainless Steel Bright Annealing Furnace

Continuous furnace suitable for bright treatment of stainless steel

| Applications | Bright treatment of stainless steel (annealing and solution heat treatment of austenitic stainless steel, quench hardening of martensitic stainless steel, and annealing of ferritic stainless steel) |

|---|---|

| Features |

|

| Temperature | 1100℃ |

| Opening width | 60 to 450 mm |

| Heating width | 600 to 5,000 mm |

BCE(B)Non-oxidation Brazing Furnace

Non-oxidation brazing, which does not require flux, is suitable for joining metal products

| Applications | Brazing in non-oxidation furnace |

|---|---|

| Features |

|

| Temperature | 500 to 1,150℃ |

| Opening width | 60 to 600 mm |

| Heating width | 600 to 10,000 mm |

| Base metals and brazing materials |

|

BCE(E)Baking Furnace for Electric Parts

Continuous heating furnace that supports processes for baking electronic parts

| Applications | Baking electronic parts |

|---|---|

| Precision temperature control |

|

| Temperature | 100~1000℃ |

| Opening width | 60 to 300 mm |

| Heating width | 60 to 3,000 mm |

| Atmosphere control | Air, H2, N2, CO2, Ar |

About the continuous bright heat treatment furnace (BCE)

Details

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat Treatment Equipment

Metal Heat Treatment Equipment