What is the Heat Treatment of Non-Ferrous Metals?

Heat treatment, combining heating and cooling, of non-ferrous metals is a process to alter the metal properties, such as hardness, softness and ductility, without changing their shapes. Examples of heat treatment of non-ferrous metals are as follows:

Examples of heat treatment of non-ferrous metals

| Metal | Copper alloys, aluminum alloys, magnesium, titanium alloys, gold, silver, etc. |

|---|---|

| Heat treatment: | Solution heat treatment, annealing, age hardening, etc. |

| Products: | Contacting materials, such as connector parts, automobile wheels, eyeglass frames, fashion accessories, automobile parts, aircraft parts and other parts |

Heat Treatment for Each Type of Metal

- Copper alloys and gold

- These metals have high ductility and repeating heat treatment processes extends them to form thin sheets. Heat treatment is performed in a nitrogen atmosphere to restrict oxidation. When quick cooling is required, a nitrogen and hydrogen atmosphere is used for cooling.

- Titanium alloys

- An argon gas atmosphere is generally used because the nitrogen atmosphere causes nitriding and the hydrogen atmosphere causes embrittlement.

- Aluminum alloys

- Since the surface is covered with a tough oxide film, aluminum alloys are generally heat treated in an air atmosphere.

Thermal equipment in this category

N SeriesReference: Heat Treatment of Non-Ferrous Metal

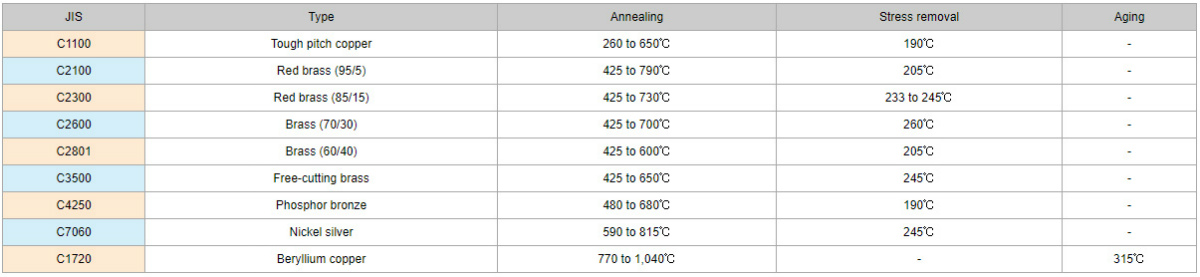

Copper alloy wrought materials

- Notes 1: Annealing softens the metal through recrystallization and crystal grain growth by heating metal hardened by cold working to temperatures higher than the recrystallization temperature.

- Notes 2: Stress removal is performed to prevent cracking due to aging, which is stress corrosion cracking, by removing residual stresses through heat treatment at temperatures below the recrystallization temperature. This process is applied to materials such as brass plates. Stress removal at low temperatures after cold working adds toughness, which improves spring properties. This technique is used for materials such as phosphor bronze plates.

- Notes 3: Aging treatment hardens the work by solutionizing the metal at high temperatures and then precipitating solute atoms at low temperatures. This process is applied to materials such as beryllium copper plates.

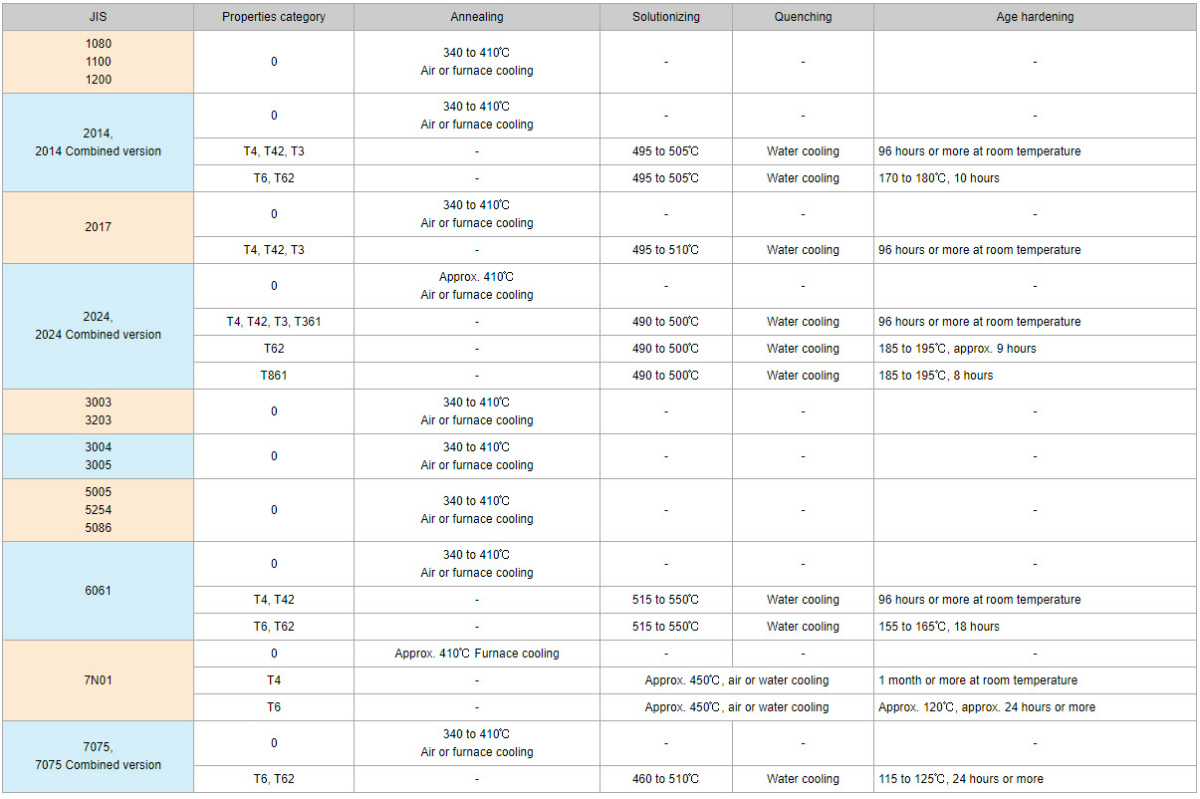

Aluminum alloy wrought materials

- Notes 1: JIS symbols for properties categories

- F: As manufactured

- O: Annealing

- H: Hardened

- T4: Natural aging after solutionizing

- T3: Cold working after solutionizing, then natural aging

- T5: Cooling after high temperature treatment, then artificial aging

- T6: Artificial aging after solutionizing

- T8: Cold working after solutionizing, then artificial aging

- T42: Treatment T4 performed by user

- T62: Treatment T6 performed by user

- T361: Cold working to 6% reduction in area after solutionizing

- T861: Hardening by artificial aging on T36

- Notes 2: Age hardening time applies to metal thickness of 12 mm or less, and 30 minutes should be added for each increment of 12 mm.

- Notes 3: Annealing of heat treated work is performed by heating the work to about 410℃, and then maintaining that temperature for at least one hour. Cooling to 260℃ at a rate lower than 28℃ per hour is advisable.

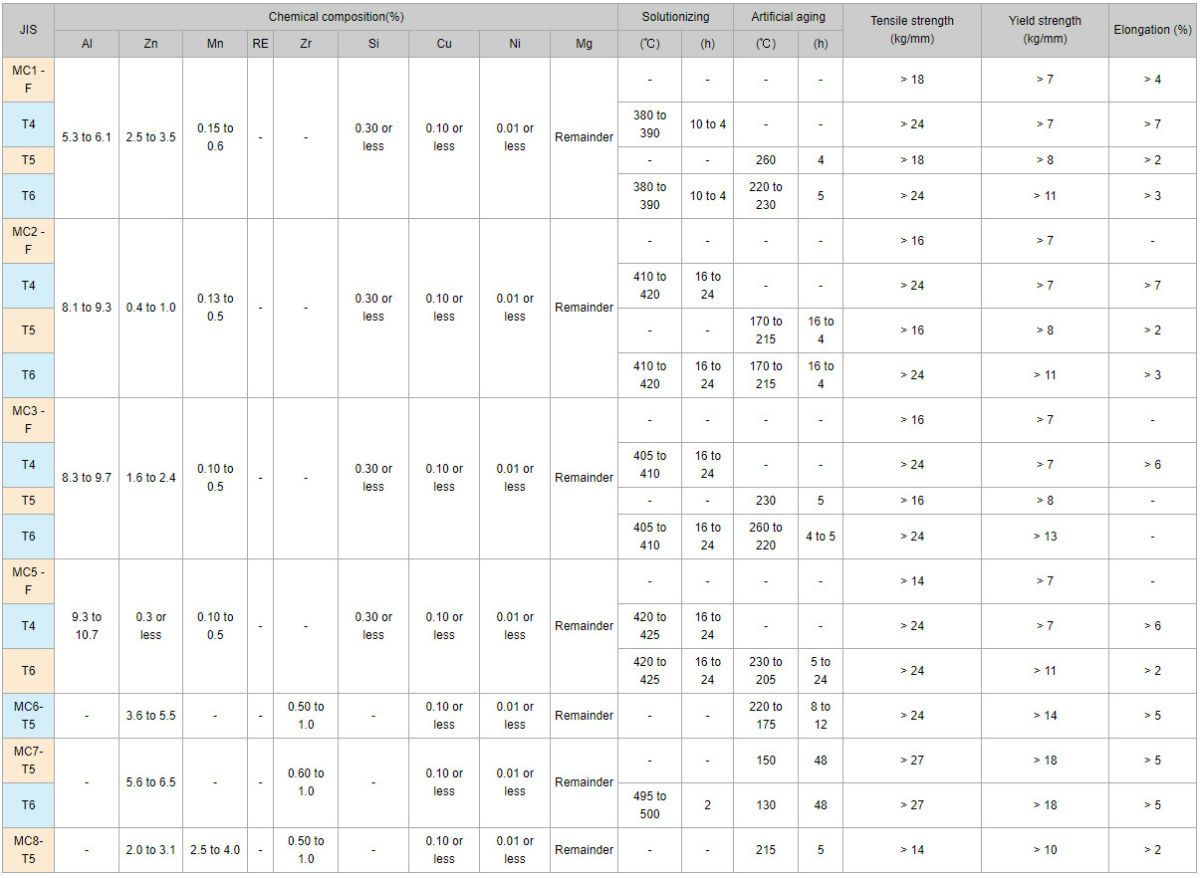

Magnesium alloy castings

- Notes 1: T4, T5 and T6 are used for magnesium castings, but T2 (cold working after high-temperature treatment, then natural aging) and F are also used.

- Notes 2: Thoroughly wash the work before heat treatment. Aluminum powder must be washed away so no powder remains.

- Notes 3: To prevent voids in Mg-Al-Zn-based alloys, gradually heat the work to the solutionizing temperature after putting it in the furnace at 260℃.

- Notes 4: Since magnesium alloys have lower sensitivity to quenching compared with aluminum alloys, air or hot water cooling is sufficient after solutionizing. However, forgings should be water cooled.

- Notes 5: Since magnesium alloys will ignite and burn at 430℃, use an atmosphere that prevents ignition in the furnace when solutionizing.

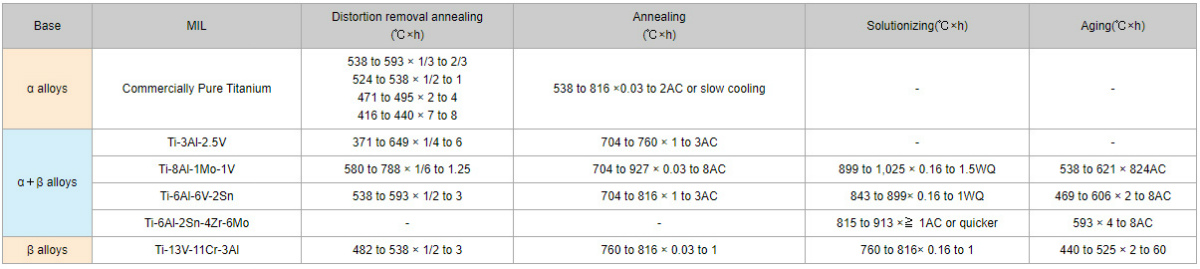

Titanium alloy wrought materials

- Notes 1: Use annealing for α alloys since solutionizing and aging have little effect.

- Notes 2: α+β alloys have high strength, but they do not allow cold working.

- Notes 3: Solutionizing β alloys improves cold workability, and aging them greatly increases their strength.

- Notes 4: Vacuum purge and an argon atmosphere are combined in the furnace to prevent oxidation.

- Notes 5: AC stands for air cooling and WQ stands for water quenching.

About furnacs for non-ferrous metals (PMR,RAV)

Details

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment