General Heat Treatment

General steel heat treatment includes the following techniques:

- Quenching

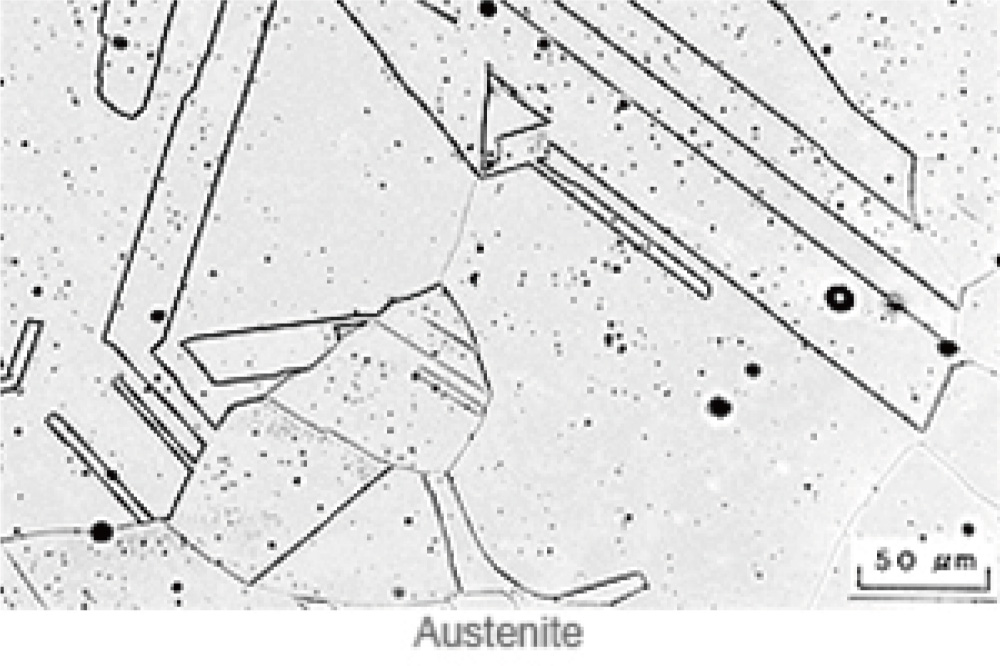

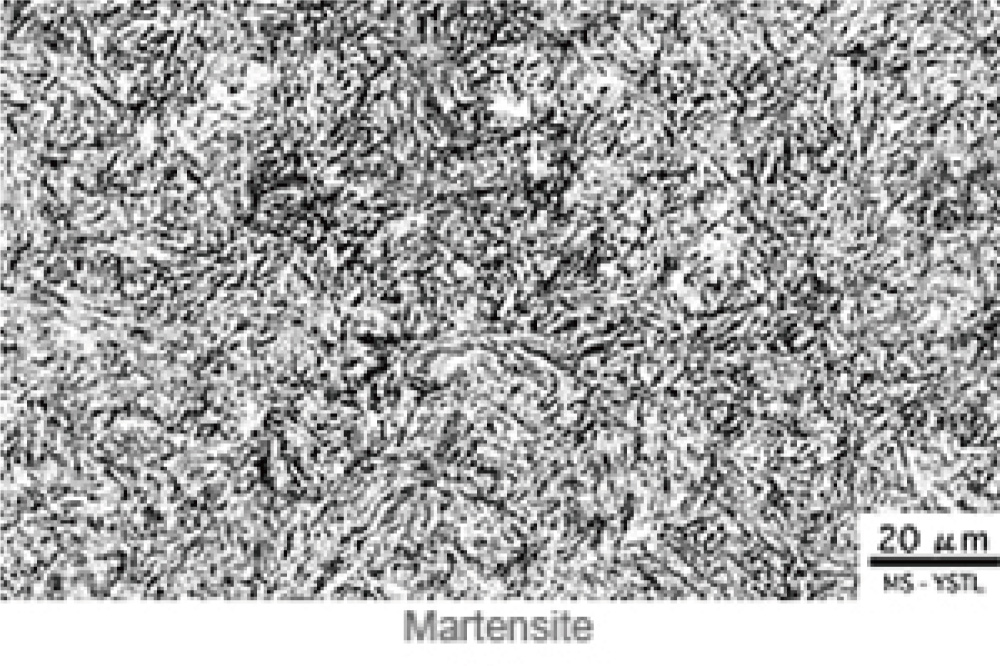

- Steel is heated to a temperature higher than its transformation point to form austenite; then the steel is quickly cooled to form martensite. This process increases the hardness and strength of the steel without changing its shape, but the steel becomes more brittle.

- Tempering

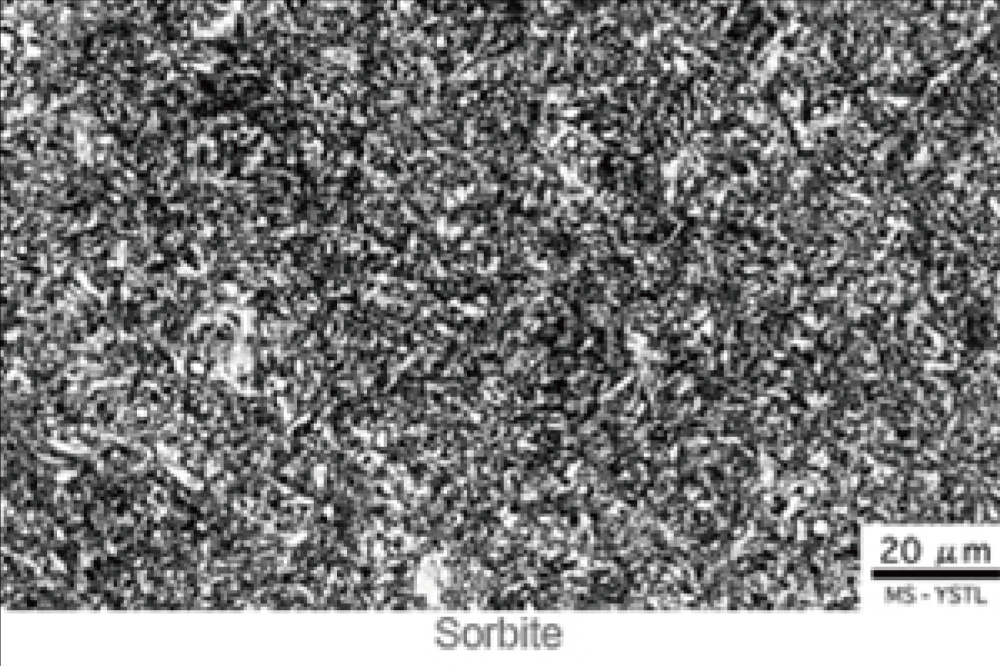

- Heating the steel again after quenching adds elasticity and toughness, transforming the steel to a structure with high resistance to wear. However, the hardness is slightly reduced when compared with the state after quenching.

- Annealing

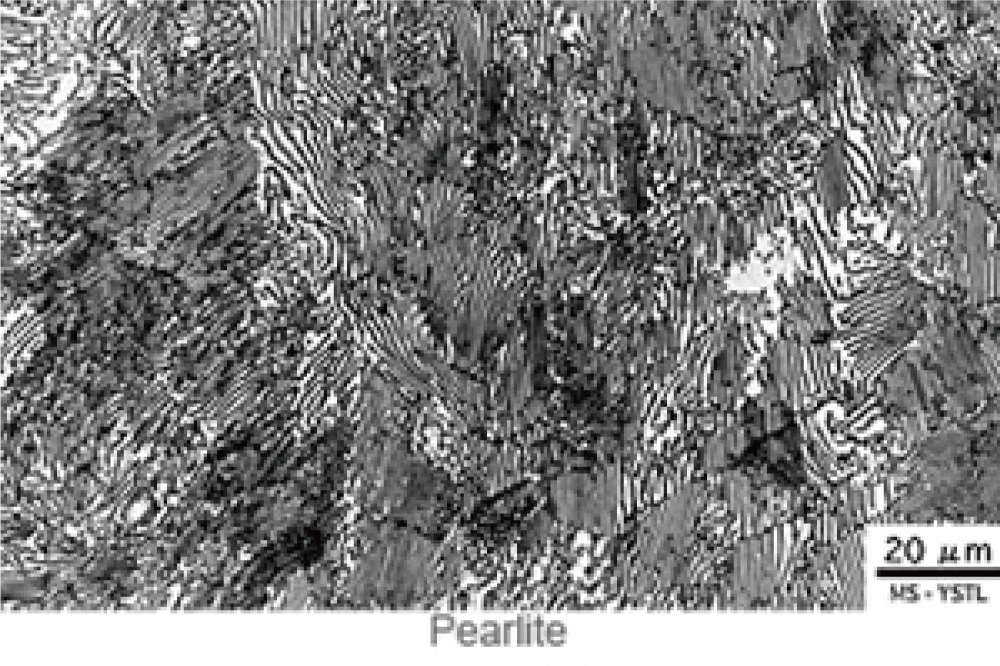

- This process is used to improve the structure and soften the steel since semi-hard steel, hard steel and alloy steel are difficult to cut due to their hardness.

- Normalizing

- This process is used to make the structure finer, uniformize carbides and remove residual stresses, thus making the steel easier to cut. Since hardenability also improves, normalizing is sometimes used as a pre-process before quenching.

Poor quenching or tempering may result in problems such as insufficient hardness, cracks, distortion and deterioration of dies, tools and jigs. In processed products such as mechanical parts, machining tools and functional parts, failures such as breaking or bending may occur after the products are built into machines, which may lead to user complaints and claims for damages.

Quenching and tempering under the right heat treatment conditions for the specific type of steel is essential to ensure the quality required for the application.

More about typical die steels and machinery structural steels.

DetailsHeat Treatment Process for Steel

The general heat treatment process for steel is as follows:

Selection of steel type

Machining

Inspection

Washing

Quenching

Washing,if oil quenching

Tempering

Post processing (as required)

Inspection

Since metal is heated to high temperatures in heat treatment, the metal combines with moisture and oxygen in the air to produce oxides, which is called oxidation. Removing these oxides by grinding or other methods is necessary in the post-process. There may also be decarburization, which can occur when steel is heated. The carbon in the surface layer combines with oxygen in the air, resulting in carbon reduction.

Thermal’s quenching furnaces (A series) can reduce such oxidation and decarburization by providing a nitrogen atmosphere in the heating chamber. Methanol or propane gas may be added to the atmosphere depending on the target work.

Surface Treatment

For products such as mechanical parts, machining tools and functional parts, surface treatment may be applied to increase the hardness of only the surface layer instead of achieving uniform hardness over the entire work.

- Carburizing and Quenching

- Nitrogen, methanol or propane gas is fed into the furnace. The gas is decomposed to cause carbon to permeate into the steel surface, creating a high-carbon steel layer only on the surface. Applying quenching and tempering to this state makes the surface harder and the deep portion moderately hard, producing a tough product.

This is a relatively deep surface hardening technique, which is widely used for automobile parts. - Nitriding

- Ammonia or another gas is fed into the furnace. The gas is decomposed to cause nitrogen to permeate into the steel surface, creating a hard nitrided layer.

Nitriding methods including hard nitriding, gas soft nitriding and plasma nitriding. Nitriding is a relatively shallow surface hardening technique, which produces harder steel than that achieved by carburizing.

The process is widely used for parts such as bearings, gears and cylinder shafts.

Thermal equipment in this category

SH SeriesTypical Die Steels and Machinery Structural Steels

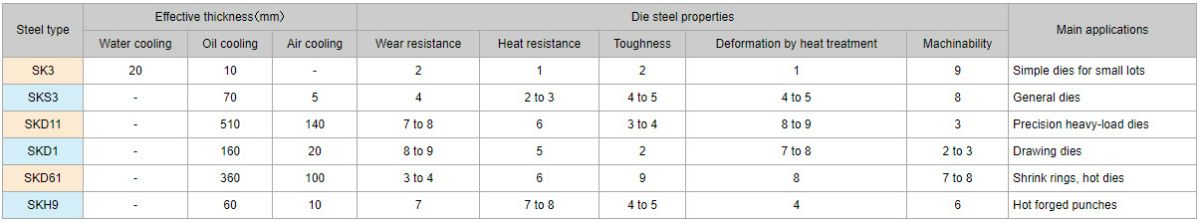

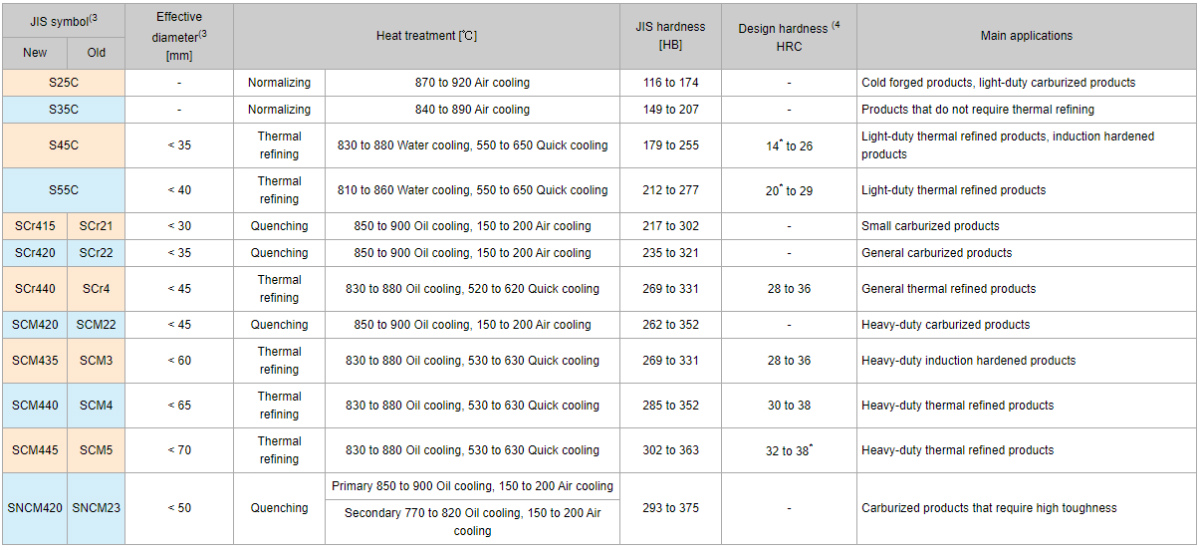

There are various types of steel; their uses and heat treatment methods vary from one another. The following tables 1 and 2 show the heat treatment characteristics of typical die steels and machinery structural steels specified in JIS (Japanese Industrial Standards).

Typical die steels

- Note 1: The effective thickness is that where core hardness of HRC60 is obtained after quenching.

- Note 2: Die steel property rating 1 is the worst and 9 the best.

Typical machinery structural steels

- Note 1: In addition to the types listed above, the following structural steels may be used.

- Manganese steel (Mangan is increased so that S38C can be oil-quenched. Example: SMn438)

- Boron steel (Boron is added to SCr440 to achieve the hardenability equivalent to that of SCM440. Example: SCrB440)

- Leaded free-cutting steel (Lead is added to SCM420 to provide a free-cutting property. However, it is inappropriate for heavy-duty gears that require Hertzian stress of over 200 kgf/mm². Example: SCM420L.)

- Note 2: In the case of alloy steels for automobiles, H steels with specified hardenability bands are used. (Example: SCr415H)

- Note 3: The maximum diameter to ensure the mechanical properties specified in JIS. This limit should not be exceeded.

- Note 4: Hardness specified in drawings may not include the upper and/or lower limits of JIS hardness, as in the items marked with an *.

About multi-function heat treatment furnace (SAM)

Details

Aluminum and Non-Ferrous Metal Equipment

Aluminum and Non-Ferrous Metal Equipment New Material Development Equipment

New Material Development Equipment Metal Heat-Treatment Equipment

Metal Heat-Treatment Equipment